Knitting the Boa Pouf

The Boa Pouf is seemingly effortless, but behind the surface, the smooth shape-knit textile that covers the Boa Pouf is a milestone in technologically innovative furniture. Follow us as we step into the knitting factory in Austria to observe the making of a Boa sleeve.

Written by Cristina Poelk Film & photography by Julian Mullan

Our Boa Pouf is seemingly effortless: A plush, foam-filled, donut-shaped lounge seat upholstered in melange wool. Behind the surface, the smooth shape-knit textile that covers the Boa Pouf is a milestone in technologically innovative furniture making that has been developed by our in-house team of engineers for many months. Follow us as we step into the knitting factory in Austria to observe the making of a Boa sleeve.

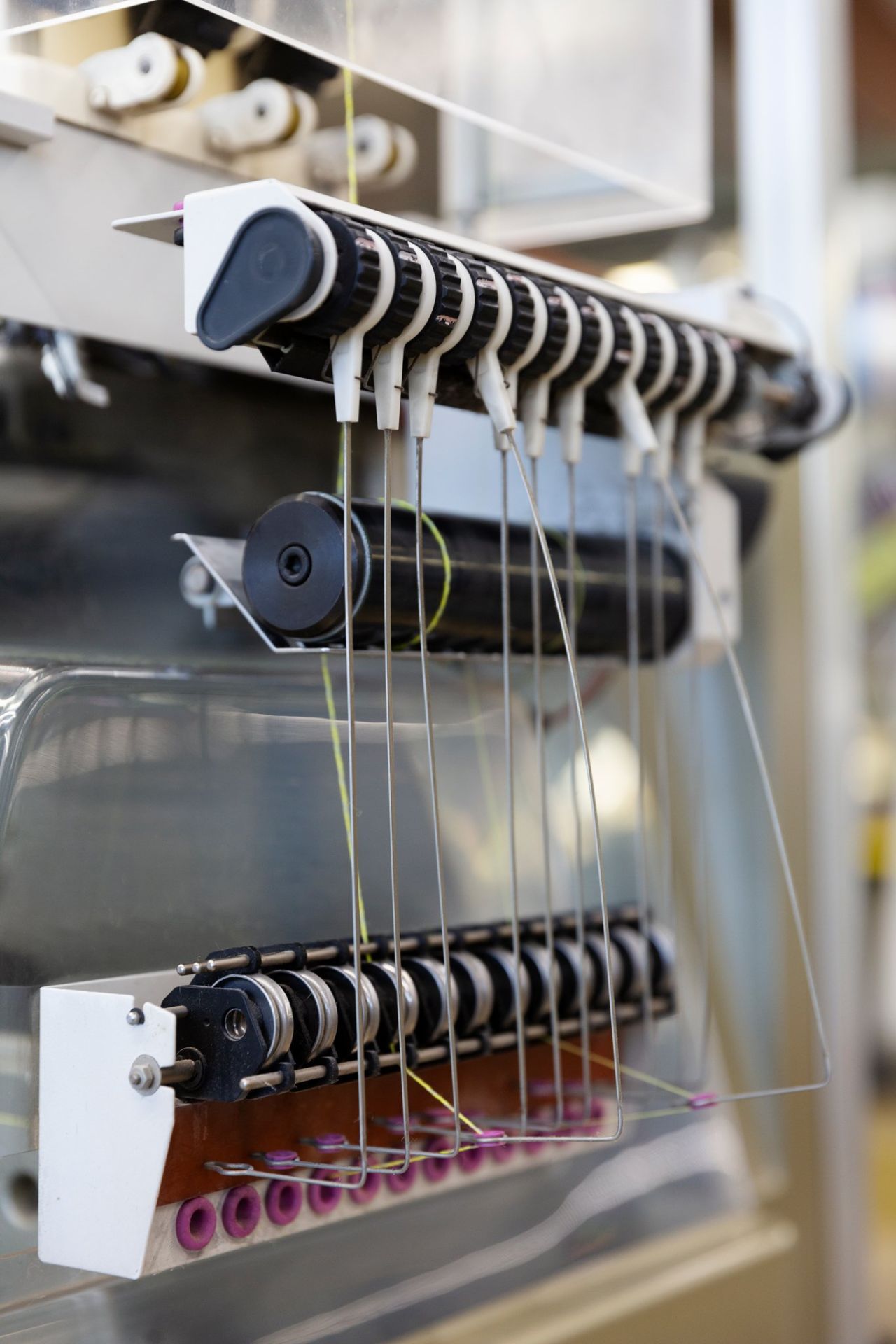

With the Boa Pouf, we use a shape-knitting technique that eliminates all visible seams or ridges, a high-tech process rarely seen in furniture design. Advancing sustainable design practice, the technique produces no scrap fabric, significantly reducing production waste. The colorful threads are fed into the knitting machine, which then creates a seamless sleeve, designed to tightly yet smoothly slip onto the naked inner foam construction of the Boa Pouf.

From inception to the final product, it took us almost two years and a dozen prototypes to refine the technique and perfect the pouf. Evocative of our progressive and experimental spirit and Sabine Marcelis’s love of color and fascination with the round donut shape, the Boa Pouf feels and appears as if naturally inflated and comes in four vibrant upholstery options, Pine, Sulfur Yellow, Cotton Candy, and Oatmeal.

“The development of the seamless, shape-knit fabric was one of the most difficult processes we’ve ever had to tackle at Hem. What we achieved with Sabine would have been impossible to create using traditional means and the final product has no precedent.” — Petrus Palmér, CEO